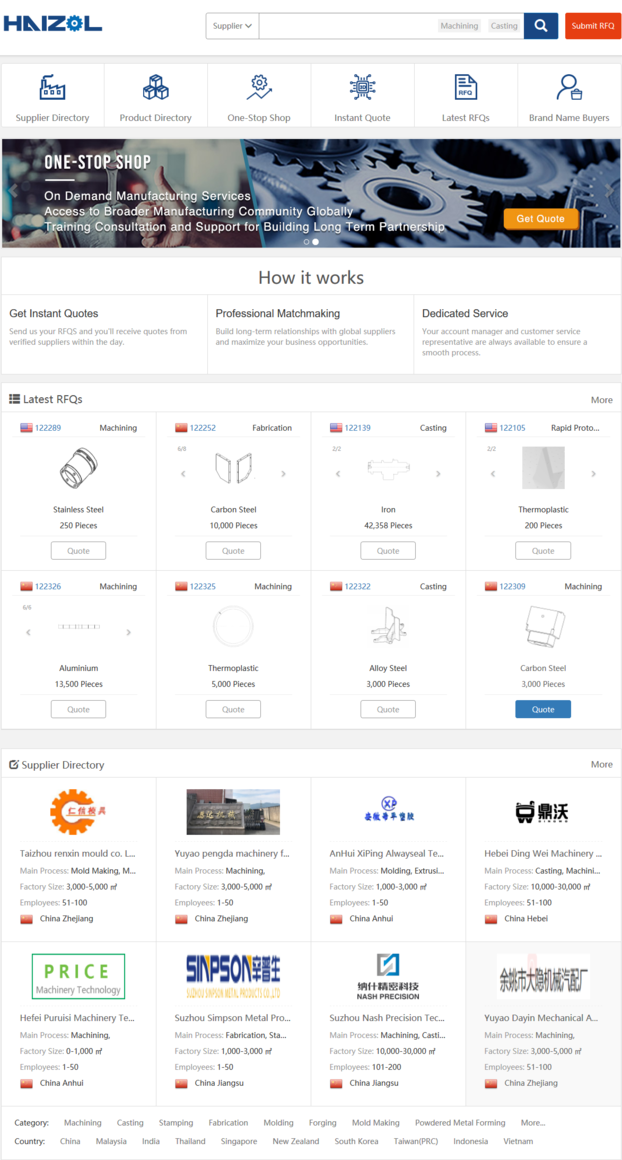

Established in 2015, HAIZOL has been dedicating itself to the processing of non-standard parts, including CNC machining, metal plate processing, injection molding, casting, stamping and die making. It had already secured five rounds of funding and developed two major business lines: the Marketplace for the online sourcing of non-standard parts and the One-stop Sourcing & Solution. With a steady focus on European and American markets, HAZOL offers customized service to different customer groups. The Marketplace caters to small and medium-sized enterprises (SME) with the intention of multiple small purchases. They can log onto the HAIZOL platform to make inquiries and upload their drawings on which HAZOL is bound by a confidentiality agreement. The inquiry, after verified by HAZOL-based engineers, will be released and open for Chinese suppliers' quotations, the fastest of which can be received within an hour. The One-stop Sourcing & Solution (OSS) is designed for enterprises in need of multiple items in multiple batches. They can purchase directly through HAZOL, which will then translate the needs to production in domestic manufacturers. By guaranteeing the production quality and timely delivery, HAZOL is well-positioned to cut the cost of sourcing management and save valuable time for buyers from overseas, thus maximizing the efficiency of cross-border sourcing.

Marketplace enabling cross-border sourcing by clearly defining customer needs and the availability of customized service

The Marketplace mainly serves European and American enterprises, especially small- and medium-sized ones, who wish to purchase multiple items in small batches. However, their needs are far from being satisfied due to the unavailability of such local suppliers as are willing to produce at low prices and the unfulfilled hope of arranging production in China resulting from multiple barriers such as language, culture, communication and trust issues. HAIZOL is given to understand the needs and pain points of the SMEs and by setting up a cross-border sourcing platform, is able to allow them to obtain quotations from suppliers registered as HAIZOL's members almost immediately after they uploading the drawings. They can receive feedback from Chinese suppliers in an hour at the soonest. All suppliers are officially verified by HAIZOL to ensure the validity of transactions. Both parties are free to negotiate without the interference of HAIZOL as a platform provider, and may enter long-term cooperation after completing the first transaction.

The HAIZOL platform is empowered by over 100,000 machining plants, 50,000 injection molding plants, and more than 90,000 mold factories across different industries. These factories, with their varied processing capacity, can enable production in large, medium and small batches and give feedback in a responsive manner. The relatively lower cost of raw materials and labor in China also make it the ideal solution for SMEs based in Europe and America.

The OSS aims to meet the needs of medium- and large-sized enterprises with large batches of sourcing needs at reduced prices. Though their products have already gained a steady share of mature markets, they see a strong demand for cost reduction, due to the increasing competition from similar products. Therefore, transferring the production of parts to China is the best choice. HAIZOL, with a perfect understanding of domestic factories, weighs sourcing requirements against their processing capacity according to the drawings submitted and singles out those who can manufacture the best parts at a relatively low price to minimize the sourcing cost. During production, a project leader will be on-site to monitor the entire production process and ensure the quality of finished parts and their timely delivery. HAIZOL's domestic supply chain team will work seamlessly with its overseas business team to facilitate their communication between buyers, maximizing time savings and improving overall efficiency.

Most Chinese factories have now secured their positions as the world's mid-range or high-end processors with great industrial support. Many key components in the automotive, medical, consumer electronics, aerospace, transportation, and engineering machinery industries are made by factories in China. Pressured by high labor costs and raw material prices in Europe and America, local sourcing has seen its profits continuing on the decrease. Many companies thus turn to Chinese suppliers via a platform like HAIZOL to maintain their competitiveness in the market, which turns out to be the best choice available.

For more information: https://www.haizol.com/en