Camfil USA, a leader in air filtration, announces exciting news for cleanroom facility engineers and all stakeholders. Their new Megalam EnerGuard offers significantly less than a 1% efficiency performance failure with lower cost compared to glass fiber and competitive filters, a longer service life, energy cost savings, operational efficiencies and manufacturing process integrity.

Riverdale, NJ, Camfil, USA, September 25, 2019, Lynne Laake, Director of Marketing, is pleased to announce at a Chicago Sales Meeting the launch of the Camfil Megalam ® Energuard HEPA filter, a game-changing filter for the life science industry. “Megalam EnerGuard is a new terminal HEPA/ULPA filter developed by Camfil specifically for the life sciences industries through years of research and application testing,” says Kevin Wood, Vice President of Camfil USA.

Pharmaceutical medical device and drug manufacturers have certified HEPA filters in their cleanrooms to protect the integrity of their products throughout the manufacturing process. In the past, these cleanrooms would require installing a high-quality micro glass media or PTFE media HEPA filter to adhere to the industry’s strict air quality guidelines.

When a HEPA filter is installed in a cleanroom, the contractor would install the filters and a certifier would test for leakage to ensure that the room met certain ISO cleanroom certification levels so the integrity of the product being produced was not compromised by contamination.

Camfil has built a revolutionary filter, with a unique media, to significantly decrease the chances of filter leaks and resultant room contamination in the cleanroom to avoid the expensive costs of a product failure during installation. The Megalam EnerGuard filter combines the best properties of fiberglass and PTFE filters and allows for better handling while still meeting required HEPA efficiency levels. Micro glass media HEPA filters have been used in cleanrooms for decades and have been the most desired option; this new robust filter has the power to become an industry-leading air filter for the cleanroom industry.

To overcome installation errors in a new cleanroom or to avoid a costly room failure event in an existing cleanroom, after four years of R&D, Camfil engineers are happy to report this major breakthrough in the HEPA filter industry. “There have been no significant changes in the HEPA filter industry since cleanrooms were conceived over 50 years ago. The Camfil Megalam EnerGuard will be the first major game-changer in 50 years,” says Charlie Seyffer, Manager of Marketing &Technical Materials at Camfil, USA.

“EnerGuard has a 34% lower total cost of ownership (TCO) vs. traditional micro glass and a 60% lower TCO vs. ePTFE.”

What Makes Camfil’s Megalam EnerGuard a Unique Game-Changing HEPA Filter & the Only Choice for Cleanrooms?

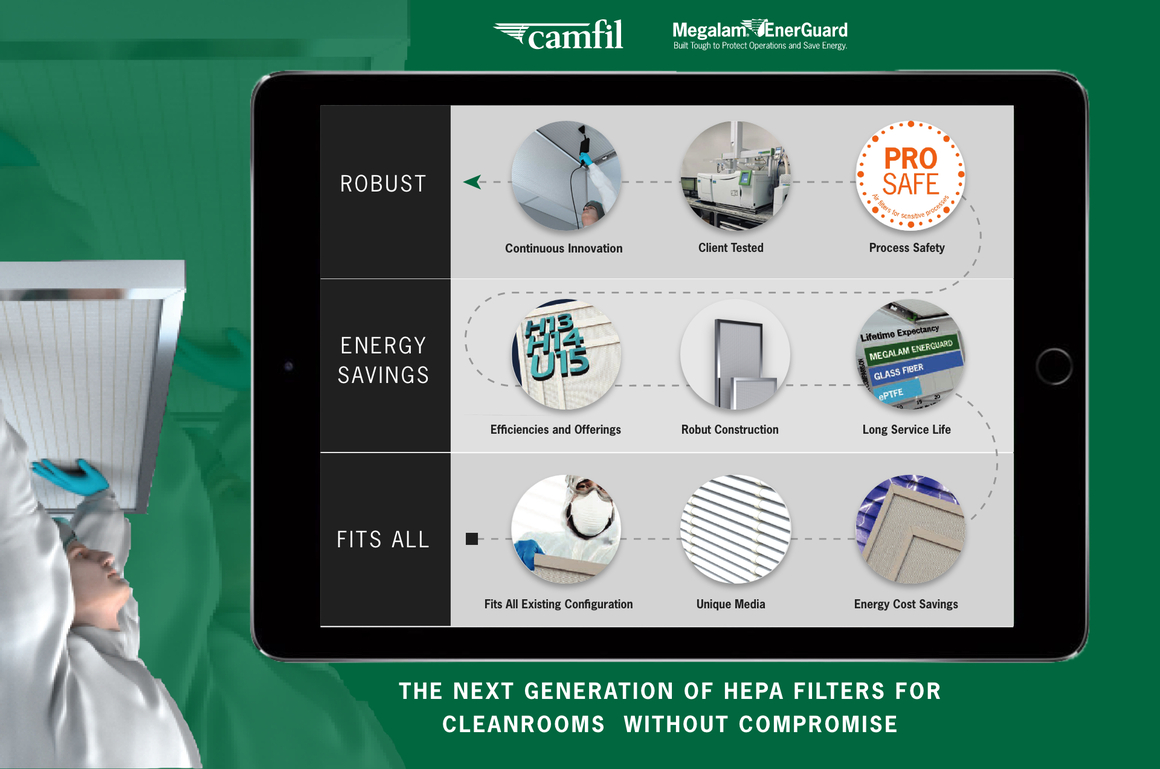

- 1) Robust Construction

The filter failure rate at installation is significantly less than 1%.

The robust nature of the filter significantly reduces the chances of product failure and expensive cleanroom downtime. Robust filters have less of a chance of damage during transportation, installation, handling, and filter service that translates to cleanroom operating profits.

- 2) Long Service Life

The Megalam EnerGuard filter life is equal to traditional micro glass media filters and lasts twice as long as other media filters.

Depth-loading media increases the effective area of particle capture substantially to maintain consistent low pressure drop and increases the period between filter replacements.

- 3) Energy Cost Savings Savings of 30% or More vs. Traditional Micro Glass Media Filters

Camfil’s new EnerGuard media is specifically designed and tested to ensure the lowest possible energy consumption.

- 4) Efficiencies and Offerings

EnerGuard efficiency is guaranteed to maintain rated values. They are available in H13, H14, and U15 efficiencies and in standard and customized pack depths.

- 5) Process Safety - Certified for Life Sciences Use

When you see the ProSafe symbol, you can be sure the filter construction materials, filter assembly and testing have been certified for use in processes with strict requirements for safety, traceability and quality control.

- 6) Client-Tested

Product approved for multiple applications based upon customer location, on-site, in-facility testing.

To learn more about how the Camfil Megalam EnerGuard offers many other benefits for cleanrooms such as:

- ● Lower installation cost.

- ● Lower total cost of ownership over 10 years of service life.

- ● Annual energy cost savings.

Now facility managers, process engineers, life sciences teams, and anyone involved in cleanroom air applications, whether it is new or existing, can have a less than 1% efficiency failure event in the cleanroom.

Released this year in North America, the Camfil Megalam EnerGuard will be available worldwide in 2020.

About Camfil

CAMFIL is a world leader in air filters and clean air solutions.

For more than half a century, Camfil has been helping people breathe cleaner air. As a leading manufacturer of premium clean air solutions, we provide commercial and industrial systems for air filtration and air pollution control that improve worker and equipment productivity, minimize energy use, and benefit human health and the environment.

We firmly believe that the best solutions for our customers are the best solutions for our planet, too. That’s why every step of the way – from design to delivery and across the product life cycle – we consider the impact of what we do on people and on the world around us. Through a fresh approach to problem-solving, innovative design, precise process control and a strong customer focus we aim to conserve more, use less and find better ways – so we can all breathe easier.

The Camfil Group is headquartered in Stockholm, Sweden, and has 29 manufacturing sites, six R&D centers, local sales offices in 30 countries, and 4,500 employees and growing. We proudly serve and support customers in a wide variety of industries and in communities across the world. To discover how Camfil HEPA Filter can help you to protect people, processes and the environment, visit us at the Megalam EnerGuard Cleanroom HEPA Filter page and download the product brochure.

Release Source: https://www.camfil.com/en-us

For Sales Inquiries:

Lynne Laake | Tel: 888.599.6620