Few characteristics in the spaces where we work and live are as important as the air we breathe. Maintaining good air quality is essential to our health and our comfort, which is why having the right air filtration is so crucial.

But how do you know if the air you’re breathing is being filtered properly? An important measure of air filtration is what’s called the Minimum Efficiency Reporting Value or MERV level of the air filter through which air is moving.

Air Filtration and MERV Ratings

Understanding MERV values and what level of filtration is appropriate for a particular space is vital, as it determines the size of particles that are removed from the air. As the United States Environmental Protection Agency (EPA) explains:

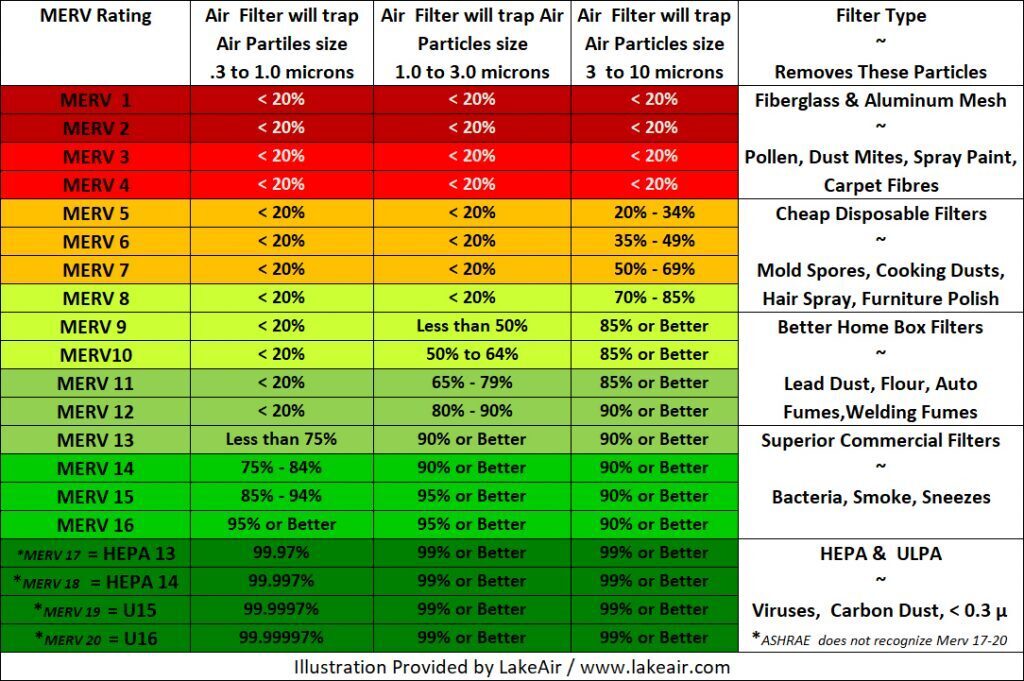

Minimum Efficiency Reporting Values, or MERVs, report a filter's ability to capture larger particles between 0.3 and 10 microns (µm).

- This value is helpful in comparing the performance of different filters.

- The rating is derived from a test method developed by the American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE).

- The higher the MERV rating the better the filter is at trapping specific types of particles.

MERV values range from 1 (minimal filtering) to 20 (maximum filtering). Levels 17 and above are used only in the most stringent of hospital or cleanroom environments, so often the scale is shown as 1-16.

Source: https://www.lakeair.com/merv-rating-explanation/

While it might seem that you should strive to have air filters with a MERV value of 20 protecting every space, that isn’t always advisable for a few reasons. First and foremost, MERV rating affects air flow, which can impact heating and cooling equipment. Specifically, the higher a filter’s MERV value is, the more tightly woven its fibers are.

As a crude visual, picture the difference between a fishing net and a coffee filter. A net wouldn’t even slow down coffee grounds attempting to pass through, let alone stop them. But the openings in a filter are so small that only fluid can pass through. The grounds are too big, and get trapped.

However, because it has large openings, a net doesn’t impede the flow of water or coffee grounds. With a filter, on the other hand, you can see how it would take longer for material to align with the openings and make its way through, with a “traffic jam” forming behind it as it does.

In a furnace or air handler, the queuing up of air to pass through a high-MERV filter creates resistance. Referred to in HVAC language as a “pressure drop,” this condition decreases airflow on the downstream side of the air filter.

That change alone is undesirable. But the more serious problem is that the decreased airflow over the part of the system that heats (in winter) or cools (in summer) the air can lead to overheating and an automated system shutdown or icing-over of the coil, respectively. And owners are left wondering why their system isn’t functioning properly.

The second reason that an especially high MERV level isn’t typically advisable is that it is, as you would expect, much more costly to implement and maintain that type of system.

What You Need To Know About HEPA Filtration

Most people have heard the term “HEPA filtration,” but far fewer understand what it means. As officially defined by the U.S. Department of Energy, HEPA stands for “high efficiency particulate air.” HEPA filters—which are MERV-16 or above—are a type of pleated mechanical air filter designed to remove at least 99.97% of dust, pollen, mold, bacteria and other particles. This is sometimes referred to as “hospital-grade” air filtration.

It’s not uncommon for people to ask for air filtration in their home or business that reaches the HEPA level. And it’s understandable that they want to protect themselves and their family or customers from airborne particulate matter.

However, as noted above, using a HEPA filter on a system not designed for it can compromise performance and damage the equipment. Additional engineering and equipment are needed to make a standard HVAC system HEPA-compatible.

And, while some people may have a medical need for HEPA air filtration, the vast majority of families and businesses don’t require it.

Why Replacing Filters Regularly Is Critical

As an air filter does its job, it traps particulate matter. This material adheres to the filter and, over time, will clog it. Ultimately a dirty filter will have the same impact on an HVAC system as using a filter with a MERV level that is too high for the equipment. Pressure drop occurs, airflow is reduced and system overheating or freezing can result.

Consequently, it is critical to replace filters regularly. A good rule of thumb is that you should change the air filter in your home or lower-traffic office space every four months. In high-traffic commercial spaces, you should change the filter every three months.

And, of course, you may have to change your air filter more often in certain environments like restaurants and processing facilities. In any setting where there is likely to be excessive airborne particulate matter, it is a good idea to examine the filter in your HVAC system frequently so you can develop a sense for how quickly the filter “loads up” with debris.

If the manufacturer of the filter you use recommends changing it every three months but you find that it is noticeably dirty after two, you should use that as your guide and change it at least every two months. The cost of a few additional filters each year is far less than the cost of a major system repair.

What HVAC System and MERV Level Is Right for Your Space?

There is no simple answer to the question, “What type of system and filter do I need?” Many factors come into play, so a conversation is really required. Do you have pets in your home? Do any family members have breathing problems? Does your business perform operations that produce airborne pollutants—things like cooking or sanding or spraying of aerosols?

Our team knows just what to ask to zero in on the right system for you. If you would like to discuss your needs or get a project quote, please contact Timberline Mechanical at your convenience.

About Timberline Mechanical

Timberline Mechanical is a Boulder HVAC Contractor located in Boulder, CO, and serving the Colorado Front Range, including Broomfield, Longmont, Louisville, Lafayette, Superior and Erie. We are dedicated to providing the intelligent solutions necessary to keep your Boulder Commercial HVAC equipment running efficiently and at its peak performance. Whether we are completing a service call request, providing Commercial HVAC Preventive Maintenance or conducting Special Projects work, we offer intelligent commercial HVAC solutions to ensure that your business needs are met. You can focus on your business while we make sure your commercial HVAC equipment is running smoothly. https://www.timberlinemechanical.com/

Timberline Mechanical Media Contact

John Kuepper

Owner

+1 303-258-3589