Phantom CNC Systems, a trusted name in the precision fabrication industry, is helping customers better understand the distinctions among CNC machine types. With a growing lineup of high-performance equipment for both woodworking and metalworking, the company outlines the key differences between various CNC routers and machines, including the popular woodworking CNC router machine and the high-powered CNC plasma cutting table.

CNC routers and machines are not created equal. Each type is designed with a specific application and material in mind. Phantom CNC Systems emphasizes this important point as customers look to invest in advanced fabrication solutions.

A woodworking CNC router machine is crafted to handle detailed cutting and carving on wood, making it ideal for cabinetry, signage, and furniture-making. These routers operate at high spindle speeds, offering fine, precise cuts through wooden panels, MDF, and other soft materials. On the other hand, a wooden CNC router machine, which is often a reference to routers working on wood, must not be confused with other router types used for plastics or aluminum. Phantom CNC’s range of routers includes models built for durability and accuracy across diverse wood types.

Metalworking demands a different approach. For these applications, Phantom CNC’s CNC plasma table is the equipment of choice. Using a high-temperature plasma arc, this table cuts through metal sheets with remarkable speed and accuracy. It's an essential tool for fabricators working with steel, stainless, and aluminum, especially in custom automotive, structural, and industrial projects. A CNC plasma cutting table is particularly valuable for shops requiring clean cuts in heavy-duty materials. This machine is also a go-to solution for efficient metal part production.

What sets Phantom CNC Systems apart is its attention to high-quality craftsmanship and robust U.S.-based manufacturing. Its CNC routers and machines are assembled and tested in-house, ensuring that each unit meets exacting standards before shipment. The company also designs its routers to be operator-friendly, with features like intuitive controls, durable construction, and integrated support for multiple cutting software platforms. Each router and machine is tailored for professional use while remaining accessible for small shops and growing businesses.

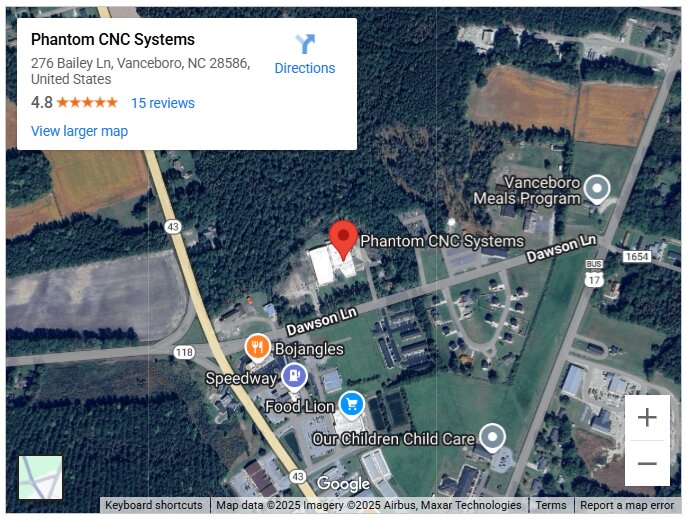

Located in Vanceboro, North Carolina, Phantom CNC Systems serves clients throughout the U.S., including small businesses, large manufacturers, and educational institutions. Its reputation for precision engineering, coupled with competitive pricing and responsive service, has made it a go-to supplier for CNC router solutions across industries. It ships nationwide and offers flexible financing to make advanced fabrication technology more accessible. Moreover, it also offers reliable after-sales service and expert support. It provides training, guidance, and resources for clients, providing them more than the machines they invested in.

Customers exploring machine options for both wood and metal are encouraged to learn how each system fits their operational needs. More information about Phantom CNC Systems’ range of CNC routers and machines can be found at https://www.phantomcncsystems.com.

About Phantom CNC Systems

Phantom CNC Systems builds and sells professional-grade CNC routers and plasma tables for woodworking and metal fabrication. Based in North Carolina, the company serves customers across the United States with products designed and assembled in the U.S.A.

###

Media Contact

Phantom CNC Systems

Address: 276 Bailey Lane Vanceboro, NC 28586

Phone: (252) 229-3896

Website: https://www.phantomcncsystems.com/

newsroom: news.38digitalmarket.com