Carbon nanotubes are awesome. Even in this era of advanced materials, CNTs show really impressive performance on multiple fronts. Their tensile strength is unmatched, they show amazing thermal conductivity along the tube, and have the potential for excellent electric conductivity and light absorption. With innovative production processes significantly lowering their cost throughout the last two decades, it is unsurprising that carbon nanotubes are such a popular material, both in research and industry. The list of uses gets longer every day, as does the list of possible future uses, currently being researched and developed. There is no doubt that CNTs are a highly versatile material.

But therein arises a problem – consistency. There are several subtypes of CNTs, with widely divergent characteristics, resulting from slight differences in their molecular structure. Additional divergence is added due to changes in the nanotube's orientation – whether parallel or perpendicular to the force applied. The more costly production methods can sort the tubes by type and properly align them, thus creating uniformly oriented, single-subtype CNT sheets, and guaranteeing perfect performance on all accounts. In contrast, the widely commercially available CNT sheets offer performance that is merely good, as they group together CNTs of different subtypes and orientation.

But there is no need to despair – a good CNT sheet can definitely be improved upon. In fact, one of the reasons CNTs are so versatile is their ability to interact with other materials and chemical compounds to change their behavior, through a process called "functionalization". In some ways, this makes carbon nanotubes an excellent substrate – the foundation upon which an even better material is created.

When looking to improve the optical qualities of CNT sheets, Acktar's black coatings are a great choice, due to their excellent adherence to CNT-based surfaces, among other useful qualities. The combination of the nanotube structure with our ultra-black coating results in a thin, lightweight material with very high light absorptance and very high thermal emissivity. Acktar's coating also protects the CNT sheet from oxidation damage, which makes for a longer and more reliable usage period. The material created can (and does) compete with the darkest black coatings on the market, both in optical qualities and resilience.

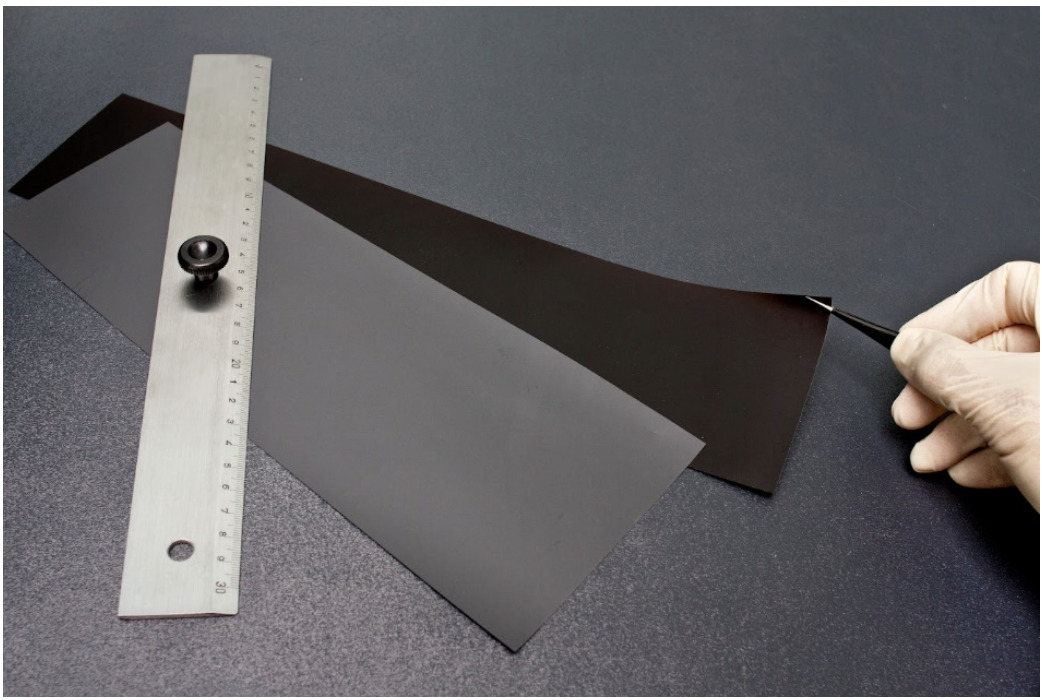

(CNT sheet – left: before black coating, right: after black coating)

Another useful aspect of this combination is on the other side of the equation - Acktar's coating does not diminish the other advantages CNT sheets possess. The coating layer is thin, so it does not add much to the base material's thickness or weight. It is inorganic and thermally resilient, so its addition can only increase the time it takes for the material to deteriorate. It is also vacuum compatible, so it is suitable for a wide range of applications, from the space industry to microchip production.

Acktar black coatings are already used improve the optical and thermal qualities of several CNT-based materials, and are incorporated in industry-leading projects, both in the governmental and civilian sectors. We are happy to help your CNT-based application be the best it can be – let us be better together.