QS Advanced Materials Inc (QSAM), a supplier of advanced research materials, has established production facilities capable of fabricating large size boron nitride (BN) machinable ceramics. These facilities can produce BN blanks up to 16" x 16" x 8" in dimension using large-scale hot presses and custom-designed molds. The capability to manufacture sizable BN blanks empowers QSAM's customers to develop large-format equipment and boost productivity. By providing access to outsized BN machinable ceramics, QSAM enables researchers and engineers to think big, design boldly, and innovate on an expanded scale.

Boron nitride ceramics have a wide range of applications, from electrical insulators to crucibles for high-temperature reactions. This versatility stems from the material's unique properties: high thermal conductivity, excellent electrical insulation, and remarkable resistance to heat and chemicals. Boron nitride could also composite with other ceramics, to form enhanced boron nitride materials such as ALNBN, BIN77 and ZCBN. In general, these materials have better mechanical properties at cost of decreasing a bit highest working temperature in inert atmosphere.

An essential aspect of BN ceramic production involves the transformation of BN blanks into finished parts through CNC machining. The size of these blanks often limits the design possibilities for BN components. However, QSAM is challenging this limitation by supplying the market with the largest available BN blanks, significantly expanding the design space for customers.

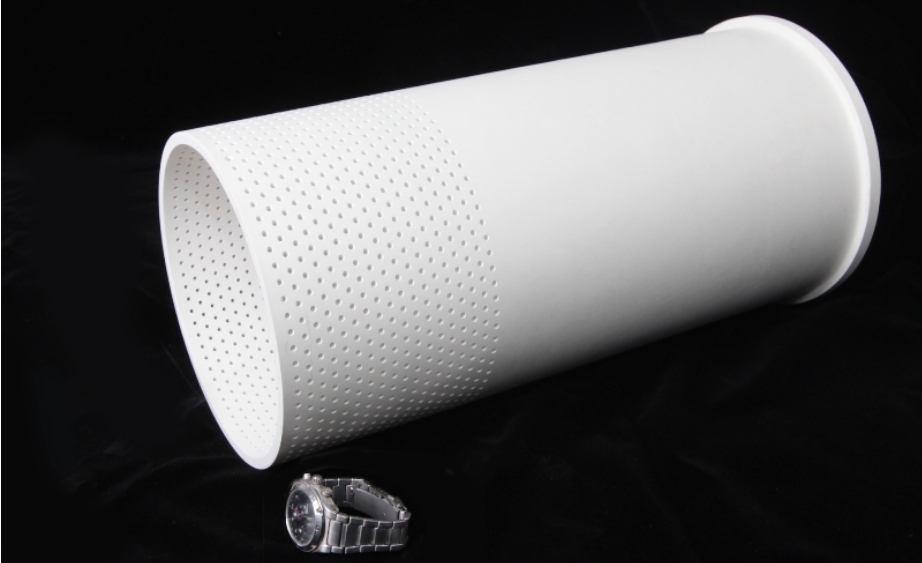

A large boron nitride component made by QSAM

Recently, QSAM's capabilities have been put to the test in a project for a client specializing in the production of exotic metal powders. Tasked with delivering large-scale >99% pure boron nitride tundishes/crucibles with 200mm diameter and more than 350mm in length. This larger sized equipment could significantly improve the productivity, compared with the earlier 100mm diameter product. QSAM utilized its comprehensive machining equipment and expertise in BN ceramics to make these parts possible.

The BN devices received praise from the client due to their increased scale and reliable performance. The larger tundishes/crucibles enabled higher production volumes, resulting in greater efficiency overall. The client was highly satisfied with the results and appreciated the improved production rates made possible by the large-scale BN equipment. Its bigger size delivered enhanced output, leading the client to commend the solution for augmenting their productivity.

This project's achievement marks an important landmark for QSAM, highlighting the prospects for large-scale BN ceramics to elevate manufacturing efficiency. By supplying top-quality, large-scale BN ceramics, QSAM is pioneering innovative approaches in the sphere of advanced materials, assisting customers in surmounting design constraints and accomplishing their production objectives. QSAM's contribution of high-performing, large-scale BN solutions underscore its role in enabling clients to push past traditional boundaries. Through its work in this domain, QSAM continues to establish itself as a leader in developing cutting-edge materials that give industries the capability to exceed production targets.

QS Advanced Materials Inc

https://www.qsrarematerials.com

Original Source of the original story >> Large BN equipment boosts production efficiency